A Beginner's Guide to Embedded Computers: Everything from Hardware to Certification

Guide to embedded computers

![]()

Some of you are perhaps not all that familiar with embedded computers but wish to find out what the area is about and how embedded computing can support your products and business. This text is for you. No previous knowledge is needed to understand the content. You don’t have to be familiar with all the expressions and concepts of the field. It’s for everyone to understand.

Questions about embedded computers? Contact us!

Embedded computer products in the Hectronic product catalogue includes product categories like complete embedded systems in enclosures, computer boards and modules, industrial displays, memory and storage products.

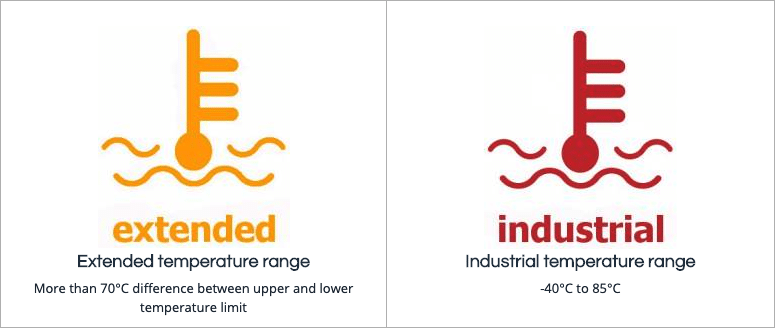

The definitions, labels and phrases used to indicate the operating temperature of embedded computers vary in our industry. Hectronic applies the following definitions to the labels Extended and Industrial operating temperature ranges in our product pages:

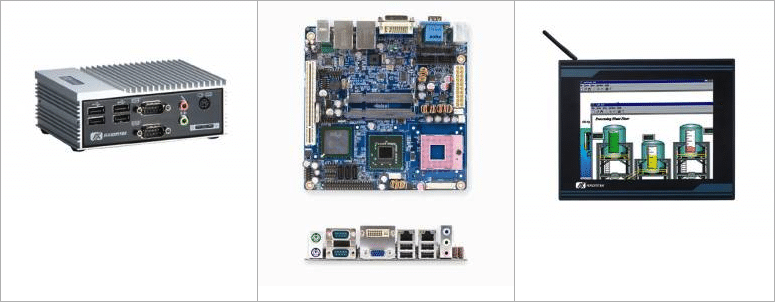

Embedded computers in the standard product category are available in separate categories. The picture shows three category examples: the fanless box PC, the computer board and the Panel PC.

The semi-custom strategy is to use a standard product, the COM (the blue smaller board), Computer-on-module and mount it on a carrier board (the green bigger board) which is custom made.