Europe demonstrates technological maturity in unmanned flying

The H6046 ETX computer module from Hectronic was used in the control system on the ground. The computer module is based on a low power Intel® Atom™ processor and the Intel® System Controller Hub US15W. H6046 has soldered memory, optional conformal coating and will be available in extended/industrial temperature range later this year making it ideal for rugged applications in harsh environments.

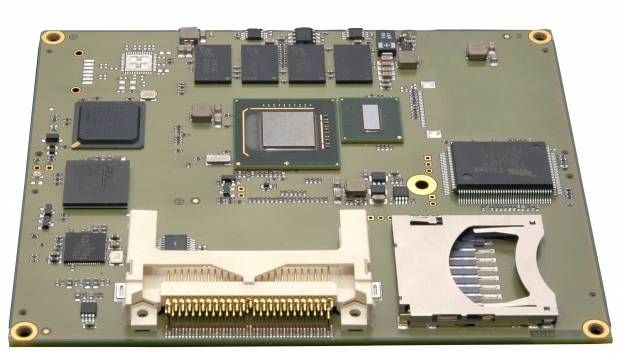

The carrier board with the Hectronic H6046 ETX computer module mounted to left and the two, redundant flight safety critical computer modules to the right. The golden metal strips separate functional blocks on the board. The aluminium enclosure is milled in compartments with walls that meet the metal strips when the carrier board is mounted in the enclosure. The design is for EMC protection.

The system to monitor and control the flight from the ground is safety critical. Two redundant units communicate with the aircraft. Two redundant system units are used in the control station.