Intel® Core™ i7 and COM Express in unmanned vehicles

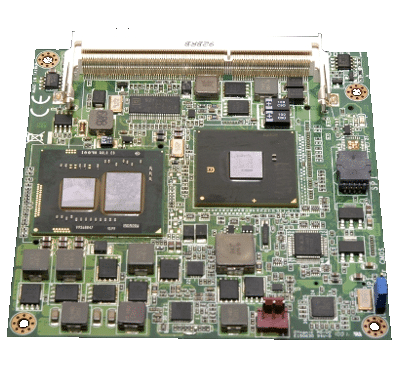

The Hectronic H6052 COM Express module is based on Intel® Core™ i3/i5/i7 processors. The form factor is COM Express Compact (95mm x 95mm) and the pin configuration in the interface between the module and the carrier board is type 2. The set of interfaces include for instance PCI, PCI Express, SDVO and LVDS.

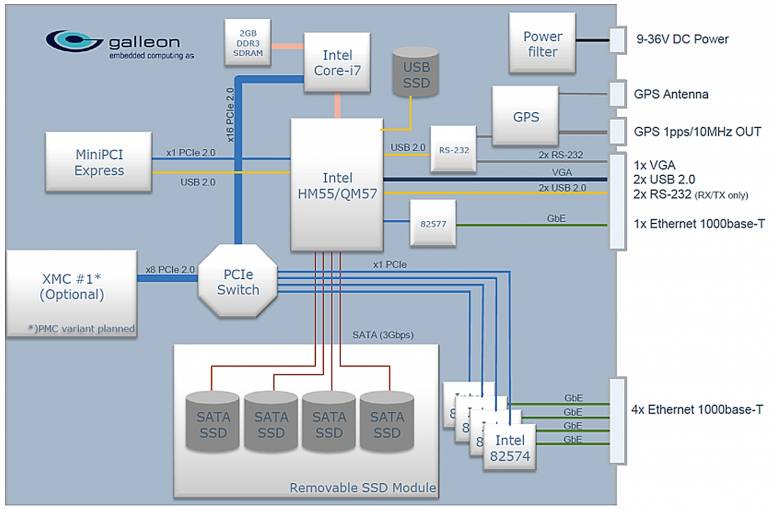

Block diagram for a system which is used for recording of data traffic through Ethernet. The direct link from the input ports via a switch to the CPU is there for maximum data speed.

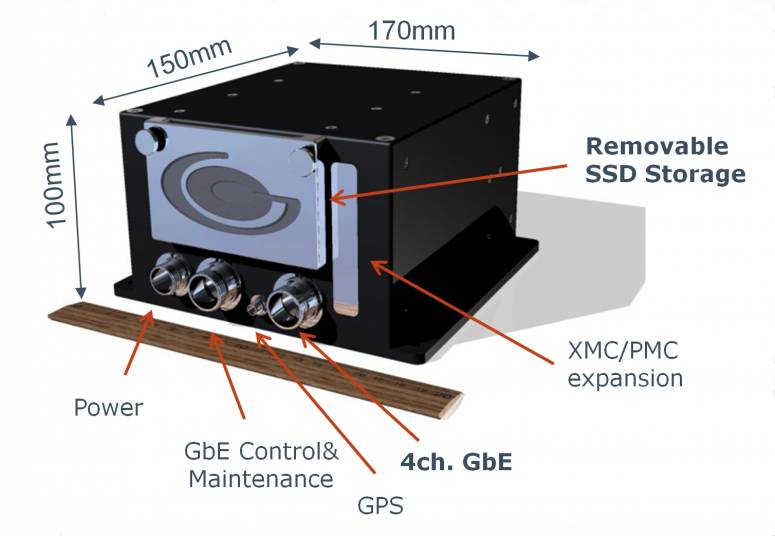

Galleon Rugged NAS is developed for network attached storage applications in demanding environments. Storage media is SSD and it’s exchangeable for rapid access to the information. It’s an important aspect to maximize the air-time for unmanned aircrafts.