IP rating

What is IP rating and why it is important

![]()

The IP rating has been around since 1979, but is now increasingly becoming more common in everything from consumer electronics to full custom embedded solutions. IP rating has always been important when developing embedded solutions. But as the environmental demands are getting tougher, the importance of knowing what the IP rating system stands for is of bigger importance when requesting an embedded solution. Here we will explain what the IP rating system is and why it is important to understand the meaning of it and how to use it.

IP Rating - Rugged Computer

What is the IP rating system?

Usually, an IP rating has two numbers and, in some cases, an additional letter, though its often excluded. The first digit describes the solution’s protection against solid materials, such as dirt, tools and accidental human contact, spanning from 0 to 6 where 0 represents no protection and 6 the most protection. The second digit describes the level of protection against liquids, spanning from 0 to 9 with 0 representing the lowest and 9 the highest level of protection. In some cases there is also a letter included in the IP rating describing information that can be connected to the level of protection.

Depending on where in the world you are buying your embedded solution from, there can be a slight difference in IP ratings. In Europe they fall in line with IEC standards 60509:1989, in the UK they are in accordance with British standards BS EN 60529:1992 and internationally they follow the EN 60529 certification.

IP Rating - Rugged Computer

Why is an IP rating system important?

There are two sides of the importance of IP rating, one for the buyer/user and one for the manufacturer. When knowing the IP rating of a product the buyer/user can feel safe in knowing how to use an electrical component in specific environments and applications. Instead of buying a product that only states that it is waterproof, which doesn’t indicate what level of water resistance they are referring to, an IP rating will clearly show the amounts of water and from which angles the product is protected from intrusion. Then it’s simple to understand in what type of environment an object is suitable to be used.

For a manufacturer, an IP rating is important from a lot of perspectives. They can rightfully claim that a product is waterproof after the object has undergone the necessary tests to get the required IP rating. It gives a product a larger amount of confidence and proof for the user that the solution will meet their demands.

The IP rating test can only be performed by an independent and certified company. After the mandatory testing is done, the solution will be given a rating that shows how well it is protected against solids and liquids. These test cannot be conducted by the manufacturer them self, which gives the whole rating system more clout and credibility.

IP Rating - Rugged Computer

IP rating charts and table

IP Rating - Rugged Computer

Dust resistance

The first digit represents protection against ingress of solid objects.

| Number | Protected against | Description |

|---|---|---|

| 0 | No protection | No protection |

| 1 | Objects bigger than 50 mm | Protected against larger parts, such as the back of a hand. But is not protected agains delibirated contact (with body parts) |

| 2 | Objects bigger than 12,5 mm | Protected against fingers and objects the same size of a finger |

| 3 | Objects bigger than 2,5 mm | Protected against tools and thick cables. |

| 4 | Objects bigger than 1 mm | Protected against wires, screws and small insects |

| 5 | Dust protected | Protected against dust as long as it is not exposed to a large amount |

| 6 | Dust proof/tight | Fully protected agains dust |

IP Rating - Rugged Computer

Liquid resistance

The second digit represents protection against ingress of liquids.

| Number | Protected against | Description |

|---|---|---|

| 0 | No protection | No protection |

| 1 | Dripping water – vertically falling when mounted in an upright position | Test time – 10 minutes. Water equivalent is 1 mm of rainfall per minute |

| 2 | Dripping water when tilted at 15 degrees. All four positions are tested | Test time – 2,5 minutes per tilt. Water equivalent is 3 mm of rainfall per minute. |

| 3 | Spraying water – up to 60 degrees from the vertical. | Test time – 1 minute per square meter (at least 5 minutes). Test time for an oscilliating tube – 10 minutes |

| 4 | Water splash from any direction. | Test time – 10 minutes |

| 5 | Water jets – from a nozzle of 6,3 mm. | Test time – 1 minute per square meter with 12,5 litres of water per minute including a pressure of 30 kPa from 3 meters. |

| 6 | Powerful jets – from a nozzle of 12,5 mm | Test time – 1 minute per square meter with 100 litres of water per minute including a pressure of 100 kPa from 3 meters |

| 7 | Submersion of up to 1 meters depth. | Test time – 30 minutes. |

| 8 | Submersion for depth of 1 meter or more. | Test time – test time and depth should be specified by the manufacturer. |

| 9 | Powerful high-temperature water jets. | Test time – test time and depth should be specified by the manufacturer. |

IP Rating - Rugged Computer

Projects

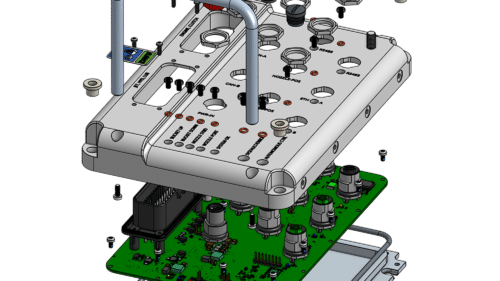

IP44 & IP56

In this project Hectronic was assigned to develop two different embedded solutions with different IP ratings. One with IP44 and one with IP56. Even though those IP ratings would be secure enough if the environmental conditions would remain steady and the solutions wouldn’t be exposed to more water then estimated, Hectronic opted to design both solutions according to IP65. This is because the solutions will be operating in environments with high amounts of humidity in the air.

In both cases the ratings demanded from the customer would have ensured the solutions to have the right amount of protection. But if the goal is to develop a long-lasting solution it’s better to be on the safe side and design the solution according to a higher IP rating.

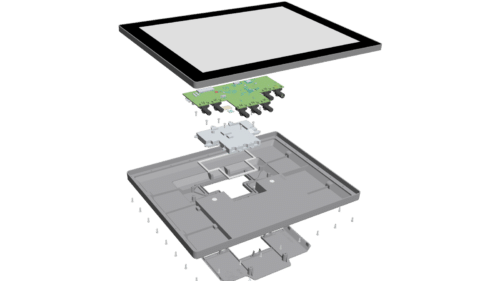

IP65

The customer required IP65 on two assigned computers, two different sets of mechanics and displays, but with the same CPU. The computers will be operating in heavy machinery working above and beyond ground level, mounted in the operator’s cab. In this case the decision was to be better safe than sorry when it came to IP classification. The environment in the operators’ cab isn’t likely to cause any damage that would require a high IP rating like IP65. But considering the operating surroundings outside the cab could vary a lot from warm to cold and dry to humid, the computer was designed according to a higher standard to ensure a longer lifespan.

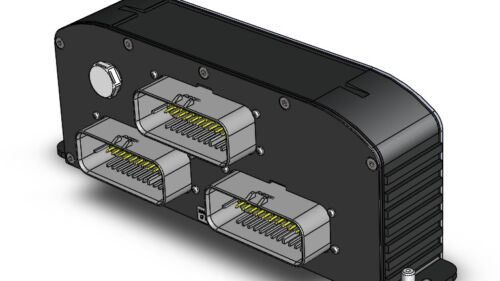

IP67

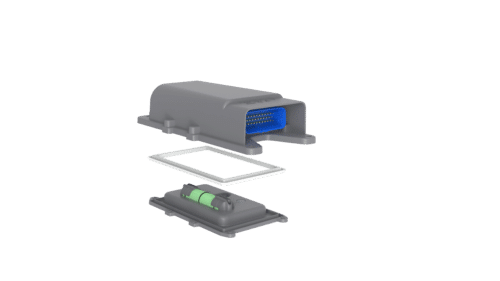

In this project Hectronic were to design a marine controller that would be mounted onto the propeller unit on a ferry. The computer would be partly under water, but also has other fields of applications in rough environment with exposure to salt water. Parts of the prior design of the mechanical housing would be reused in the design of the new application. The new application has two PCB’s instead of three, one CPU board and one connector board. The front panel, back panel, gaskets and Gore-Tex membrane will be re-used from the current design and the shortened extrude will create a simpler and cost-effective design.

IP69

This is a computer developed for extremely harsh environment. The computer is to be mounted openly on a truck. It must be able to withstand water from a pressure washer and tough enough to fully function even though its operation on a moving truck exposed to the elements.

This project is still under development.