Key to product life cycle management

|

||||||||

|

Technical development and time to market are important aspects to reach business goals for our customers. Discussions about the importance of product maintenance to maintain production at a preserved level of quality is not so common though.

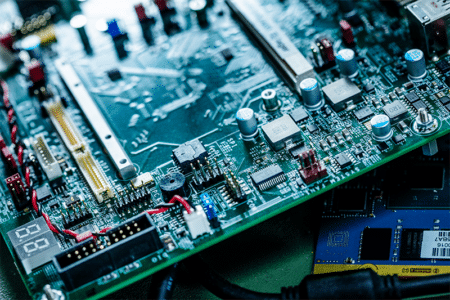

The lifetime of the processor and chipset of an embedded platform is typically about ten to fifteen years. Systems based on the platform often have a BOM consisting of a couple of hundred components. In order to realize the maximum prolonged life time of the platform one or two (or more) components are bound to need to be replaced during the life time of the product.

In this context Hectronic’s contacts at suppliers’ and manufacturers’ are valuable. When one of the many components in a product has gone end of life directly we’re informed. The complexity of the component, its role in the design and the requirements put on production by the quality management system of the customer decide the amount of work needed to find a replacement, verify the functionality and put it into production.

|

||||||||

|

|

||||||||

Engineering judgment from the development team |

||||||||

|

Resistors, capacitors and plain mechanical details like screws and standoffs are uncomplicated and straightforward to replace in the BOM which is updated by the Technical Product Manager. More complex components like I/O controllers, memory and storage require more resources, familiarity with the design and engineering judgments. This process usually involves the hardware engineer responsible for the board design and the software engineer with insight in the BIOS in question.

Since all competences required to develop a complete embedded system are there, at Hectronic, in-house, it’s quick and easy to gather the appropriate team for deliberations and judgments. To replace memory components have proven particularly challenging. High-speed buses and critical timing issues is the reason why it sometimes doesn’t work even though it should according to the datasheet.

Replacing memory components may require adaptations to the BIOS in order to work. Some systems adapted to harsh conditions are sometimes required to undergo temperature cycling in our temperature chamber from the lowest to the highest operating temperature in the range.

|

||||||||

|

|

||||||||

Reusing verification of building blocks |

||||||||

|

Hectronic has had the principle of reusing building blocks ever since the company was founded. We argue that the benefits for our customers are that development is fast, reliable and cost-effective. The advantages are there in product maintenance as well. Power circuitry is an example of a building block which is used in numerous designs of computer boards and systems. So if a critical component in the power circuitry needs to be replaced it is enough to verify functionality of the power circuitry with the new component in only one product. Thereafter it’s safe to use the new component in all computer boards, modules and systems where the particular power circuitry is used and in production.

According to the procedures used when Hectronic replaces an end of life component with a new one in the BOM a new release of the product is made only after verification is performed. For Hectronic’s customers with strict requirements on quality assurance, such as in medical technology, these procedures are crucial to the customer’s quality management system. Such a customer is informed and involved in the process. To other customers these procedures are performed in silence.

|

||||||||

|

|

||||||||

Getting the most years out of the product |

||||||||

|

By way of introduction, product maintenance was described as the means to get the most life time out of the processor platform and the product in which it’s used. Additional product lifetime may be obtained through buying and stock-keeping of the processor and the chipset when the platform is reaching the end of its life span.

The typical ten to fifteen years, and maybe some more, have passed and the inevitable generation shift of the product is coming. We’d need to remind you that Hectronic has an impressive track record of developing a new embedded computer, not only with the new cutting edge computing technology, but also fulfilling requirements for compatibility with existing software, hardware and equipment connected to the product, but that’s another story.

|